Thoughts While Building an IKEA Alex File Cabinet

I spent two hours building two IKEA Alex drawers and had a lot of thoughts along the way, from questioning the instruction manuals to wondering why they don't tell you to batch things.

Audio Companion

Total time building two Alex drawers: ~2hours

15 minutes in: Whoever is the motherfucker who makes instruction manuals[1] for IKEA is a sadist of the highest order. Who are these Keith Haring looking motherfuckers? Why are they so condescending?

19 minutes in: Nothing like some particleboard in the lungs to wake you up. I probably should've wore a mask for this…

34 minutes in: Fuck it I’ll just hit it with a hammer

38 minutes in: If you’re going to make such a small distinction about screws that look the exact same, why put them in the same fucking bag???[2]

44 minutes in: The instruction to put it upside down was a great call. Author's note: This brief joy was

immediately canceled out by having to turn the weird screw from the bottom.

bramadams.dev is a reader-supported published Zettelkasten. Both free and paid subscriptions are available. If you want to support my work, the best way is by taking out a paid subscription.

44 minutes in: Why don’t instruction manuals tell you to batch things, do the honestly expect people to do these one by one? Looks like someone got stuck on bubble sort at school ;)

IKEA Engineers Should Unionize

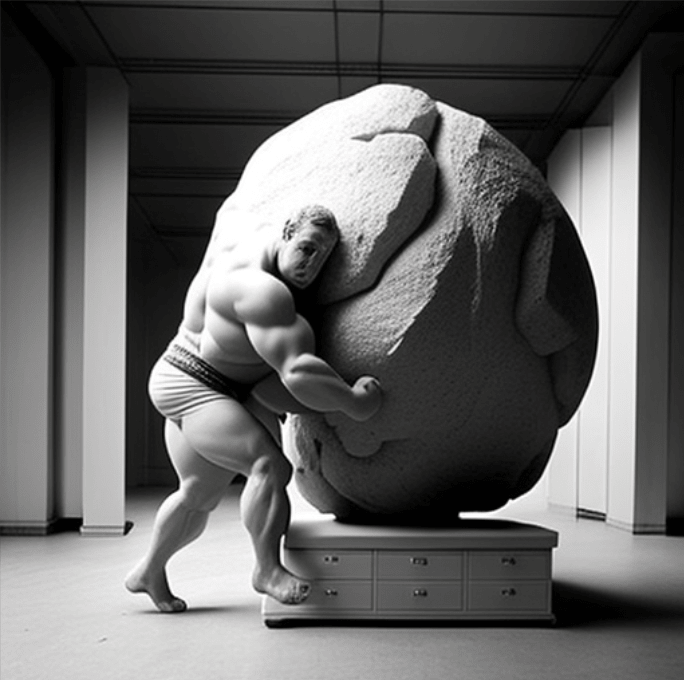

A newspaper in Sweden described Ikea [furniture assembly] as something between civil engineering and captaining a submarine, and I think that’s a good description,” says Allan Dickner, Ikea’s deputy packaging manager. (View Highlight)

there’s one foolproof method for turning Ikea rage into grudging respect: assembling almost any other brand of furniture. After an hour spent comparing piles of ambiguous components against an assembly diagram that looked like a misfiled mimeograph from Area 51, I somehow produced a HomeGoods end table—as well as a surging curiosity about how Ikea designs its own packaging and instructions, which now seemed positively Eamesian in comparison. To adapt Winston Churchill’s famous quip, Ikea may be the worst form of ready-to-assemble product design we have—except for all the others. (View Highlight)

According to Allan Dickner, whatever your most frustrating Ikea experience is, it could have been worse—and most likely was for the packaging engineer who test-assembled even more complicated versions of the product before arriving at the optimized design that you unboxed on your living room floor. “We had one furniture piece, a type of wardrobe, which originally had over 400 fittings and screws to hold it together,” Dickner says. (View Highlight)

For 400 screws that wardrobe better open straight to Narnia, shit.

Continuity, meanwhile, is what separates Ikea’s instructions—even the maddening ones—from those of other brands. The Lego-like, frame-by-frame illustrations are based on construction drawings, digital snapshots, 3-D models, and videos of test assemblies. Designers take pains to render each successive picture from a single, unchanging point-of-view (mimicking that of the customer), so that confusing rotations or perspective changes are minimized and the customer can stay oriented more easily as he or she moves back and forth between the booklet and the parts. (View Highlight)

*Turns on isometric view mode in Blender once*

They may not be pleasant, but they are at least rational and comprehensible—even sympathetic—by design. Think of that big-nosed “Ikea man” who’s shown calling the company when he gets stuck. He’s not mocking or condescending. If anything, he represents some designer at Ikea who has already gone through exactly what you’re going through now on your living room floor: half-quizzically glancing from instruction booklet to pile-of-parts and back, hoping for the best, but trusting that it will all, at the very least, make sense. (View Highlight)

I disagree.

The Moving Sofa Problem

“It would be quite stupid to design a package that’s flat and efficient but won’t fit into a small elevator or staircase,” Dickner explains. “It sounds ridiculous, but in the United Kingdom, that was one of the most frequent reasons for a customer returning a product.” He adds that global package designs are tested in Japan and South Korea “because those are the customers who live in the smallest spaces.” (View Highlight)

The Europeans get math(s)ed by their hella small flats.

the moving sofa problem or sofa problem is a two-dimensional idealisation of real-life furniture-moving problems and asks for the rigid two-dimensional shape of largest area that can be maneuvered through an L-shaped planar region with legs of unit width.The area thus obtained is referred to as the sofa constant. The exact value of the sofa constant is an open problem (View Highlight)

He's made quite the compelling career for himself…202301051907

products like these make me appreciate well made tech products even more, tbh 202301130214